Simple and convenient solution for securing fixing of water-soluble paper on a workpiece

Water-soluble film

Water-soluble film Rusolvo is a transparent gas barrier during argon-arc welding.

Rufilm is to be used as a purge gas barrier in the process of argon-arc welding. This film is the most cost-effective alternative to local pipe purge purpose during argon-arc welding, since the total pipe purge involves considerable expenditure. Rufilm is a completely biodegradable, water-soluble product.

It is suitable for different kinds of steel and alloys of every pipe diameter. Film with dimension of 1*20 M is available in rolls and briquettes.

The unavoidable obvious advantage of the film is the fact that it can be placed in close proximity to the weld zone that allows less inert gas usage, leading to costs lowering for the overall welding operation.

Moreover, after the welding is done, the film is effortlessly and rapidly dissolved during water or steam hydro-test, which leads to a significant reduction in the cost of removing the dam from the pipe.

Sizes of Rufilm:

| Item No. | Dimensions | Type |

| RFR | 1*20 M | Roll |

| RFB | 1*20 M | Block |

| RFA (Glue) | 250 ml | Bottle |

Rufilm is all-purpose purging device as it's possible to cut the desired size for any pipe diameter. Gas inlets and outlets can be made by puncturing with little risk of tearing and has high-force resistance enabling the weld area to maintain greater level of positive pressure.

How it works

|

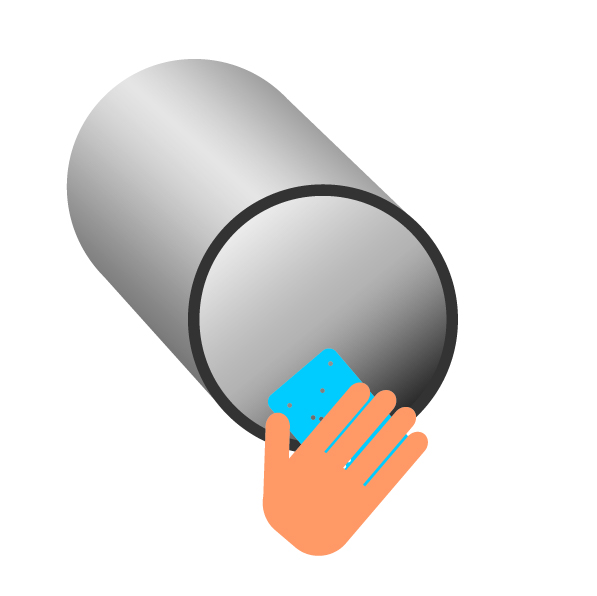

1.Preparation

|

Clean inside of pipe, removing contaminants from the surface. |

|

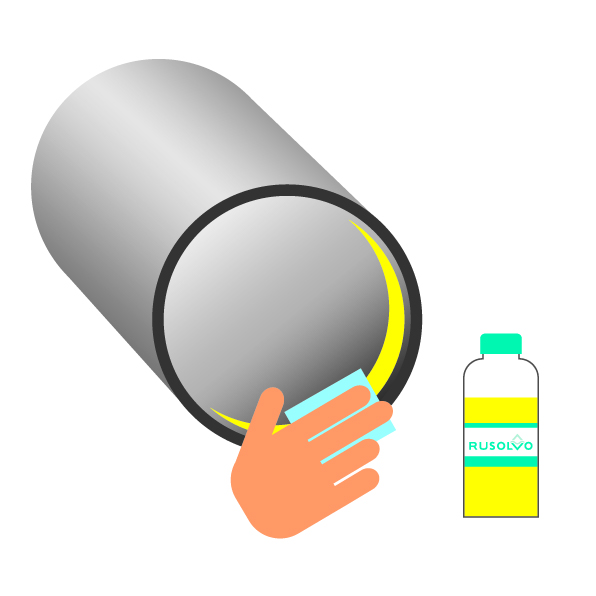

2. Adhesive coating

|

Apply water-soluble adhesive to inside of pipe. Evenly coat the entire circumference of the pipe surface where film is to be placed. |

|

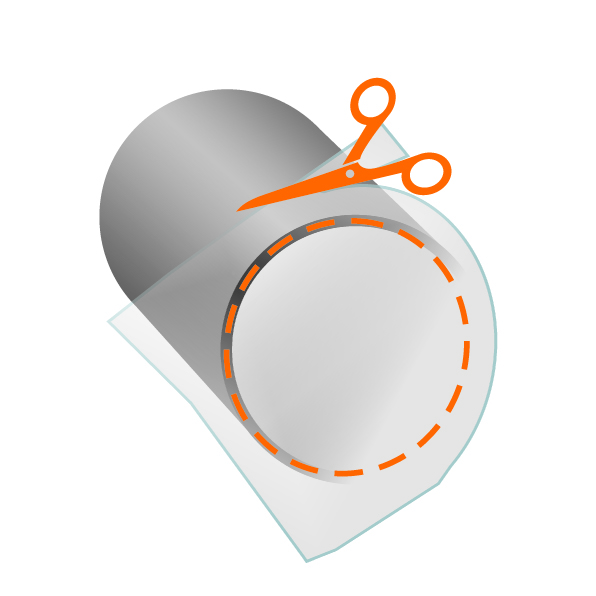

3. Sizing up

|

Trace pipe’s inner diameter by pressing Rufilm along pipe edge, creating an impression. Cut Rufilm in a circle around the impression, approximately one-third times greater than pipe diameter. |

|

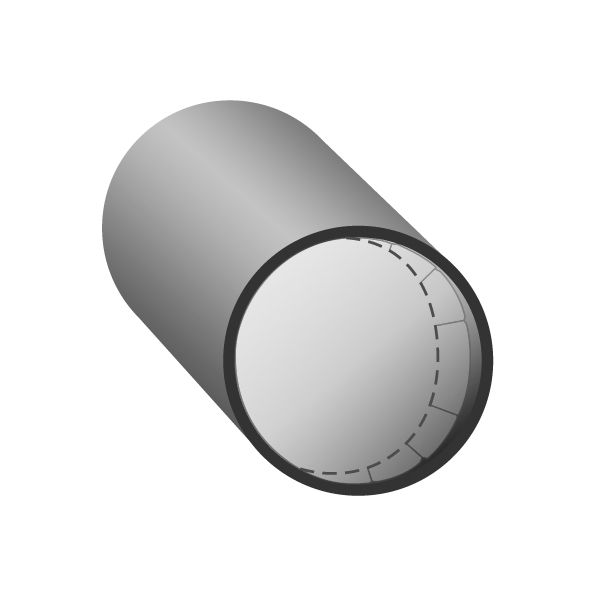

4. Fixation

|

Press glossy surface of Rufilm against tacky adhesive inside the pipe to create an air tight seal. If needed, puncture a small hole in the center of the purge dam to allow oxygen to escape. |

| Pipe diameter | 48-205 mm | 205-561 mm | 561-920 |

| Recommended distance from the welding area | 152 mm | 203 mm | 305 mm |