Simple and convenient solution for securing fixing of water-soluble paper on a workpiece

Water-soluble paper

This paper IS a proven and eco-friendly solution for more effective inert gas usage during welding process.

Rusolvo is an ideal barrier for creating perfect purge environment by means of inert gas restraining in the weld zone, and also it does not require any special removal procedure, since it is easily dissolved during the water or steam hydro-test.

Technical characteristics of water-soluble paper Rusolvo:

|

Item No. |

Thickness |

Dimensions |

Type |

Case pack |

|

RPS-39/50 |

0,2 mm |

390 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS-52/50 |

0,2 mm |

520 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS-79/50 |

0,2 mm |

790 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS1-39/50 |

0,1 mm |

390 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS1-52/50 |

0,1 mm |

520 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS1-79/50 |

0,1 mm |

790 mm*50 M |

Roll |

Box/4 rolls. |

|

RPS1-42/56P |

0,1 mm |

416 mm*560 mm |

Pack |

500 sheets |

|

RPST-1 |

0,08 mm |

25 mm*90 M |

Roll |

Box/24 rolls. |

|

RPST-2 |

0,08 mm |

50 mm*90 M |

Roll |

Box/24 rolls. |

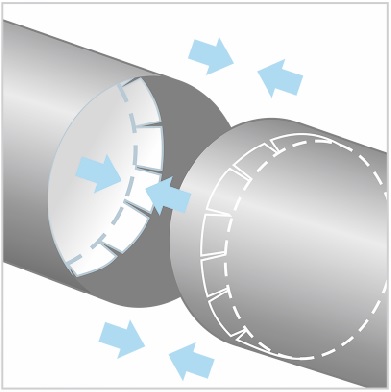

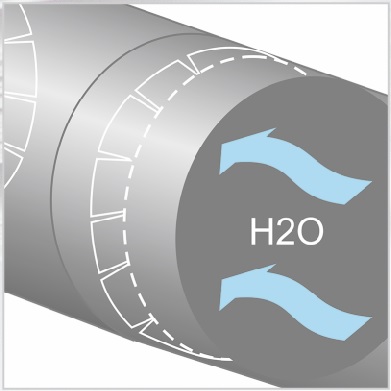

Our water-soluble paper is a certified, effective, and eco-friendly purging solution during the welding process. It is used for inert gas retaining in the process of argon arc welding of stainless steel and alumium pipes. Rusolvo can be used as a purge dam. It is suitable for every pipe diameter and could be placed in close proximity to the weld zone, thereby using less inert gas to displace oxygen in the purge chamber.

The paper easily dissolves in water and the most of aqeous solutions, leaving no residue in the pipeline.

The paper is available in a wide range of sizes and grades, absolutely safe that makes it perfect for nuclear, petrochemical, food and beverage industries.

Technical chracteristics and advantages:

- Fast and simple construction that can be customized to fit various pipe schedules and sizes;

- Ensures the inert gas environment retaining and at the same time eliminates the supply of oxygen;

- Saves money on gas consumption as paper can be placed in close proximity to the weld zone, thereby using less inert gas to displace oxygen in the purge chamber;

- Easily secures to inner pipe wall with use of water-soluble tape, creating an air-tight seal;

- 100% biodegradable and eco-friendly material: sodium carboxy methyl cellulose and wooden pulp;

- Perfectly suited for nuclear, petrochemical, food and beverage industries;

The effortless removal process:

- Dissolves effortlessly and rapidly during water or steam hydro-test;

- Avoids the necessity for post-weld cleansing;

- No residue remains in the pipeline;

- Eliminates the necessity of further work, connected with the purging device removal from the pipeline, that saves time and cost;

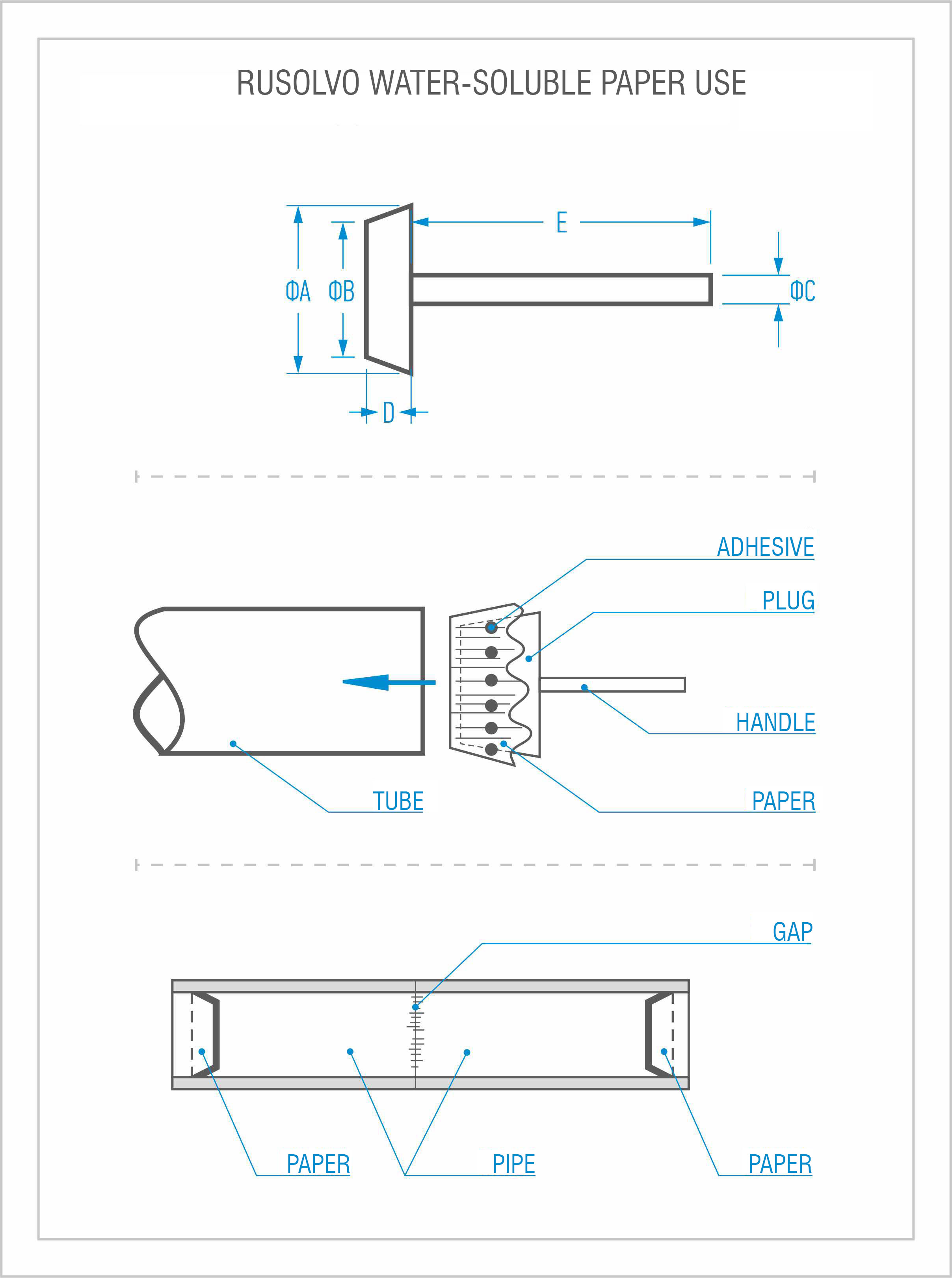

How it works:

|

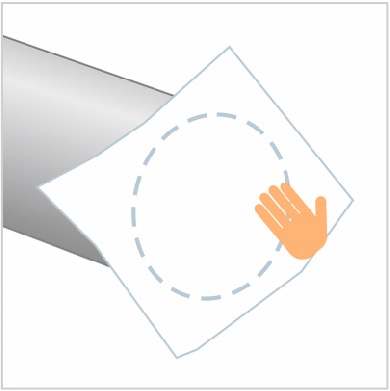

1. Measure a diameter

|

First of all, trace pipe’s inner diameter by pressing paper along pipe edge, creating an impression.

|

|

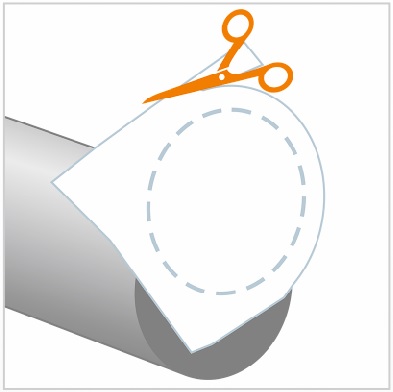

2. Make a measurement

|

Measure a diameter of the circle impressed on the paper, cut in a circle around the impression, approximately one-third times greater than pipe diameter.

|

|

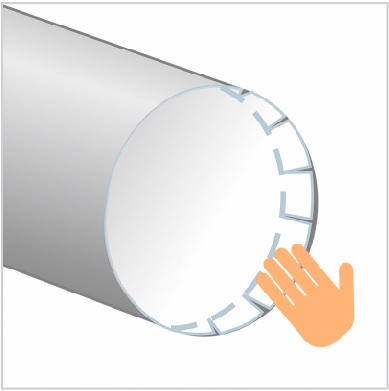

3. Slit

|

Slit approximately 10 mm to 20 mm segments perpendicular to impression on paper making first slit at 12 o’clock position followed by 3 o’clock, 6 o’clock and so on. THe slits themselves should range up to the impressed pipe diameter.

|

|

4. Position inside of Pipe |

Get water-soluble tape Rusolvo ready - to achieve that, cut it into some even pieces, their length may vary depending on a pipe diameter. Position slit Rusolvo water-soluble paper dam inside of pipe. The dam should be placed at the recommended proximity (chart 1) from the weld area. Secure dam with tape pieces along the entire circumference.

|

|

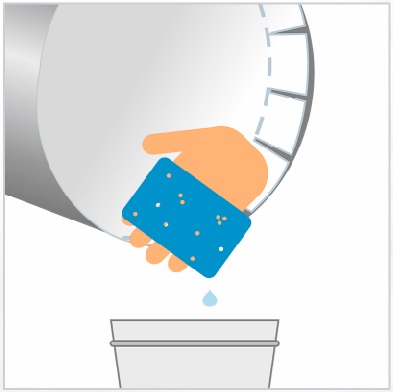

5. Moisten sponge

|

Moisten a sponge with water and squeeze out the excess of water until sponge is damp.

|

|

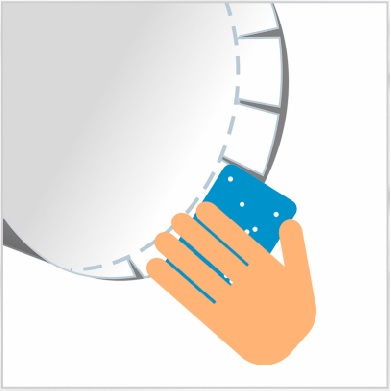

6. Activate water-soluble tape

|

Lightly dab sponge along the water-soluble tape portion of the dam. The dampened sponge will reactivate the adhesive to ensure low air permeability.

|

|

7. Repeat

|

Repeat the process on the opposite side of the pipe at the recommended proximity from weld area to close the purge chamber parameters (chart 1).

|

|

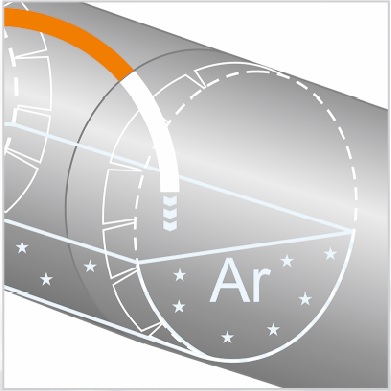

8. Introduce inert gas

|

Insert purge gas needle into root gap and introduce inert gas, ensuring connection to gas line. |

|

9. Dissolve the purge chamber

|

Introduce water during the performance of hydro-test, this will help to dissolve water-soluble paper and tape effortlessly and rapidly. |

|

The recommended distance of water-soluble chamber from welding seam |

|||

|

Pipe diameter |

48-205 mm |

205-561 mm |

561-920 mm |

|

Recommended distance |

152 mm |

203 mm |

305 mm |

Water-soluble paper with hand-made plug usage pattern (without using water-soluble tape)